Barcode Generator 128, a powerful tool for creating and managing Code 128 barcodes, opens up a world of possibilities for streamlining data management, inventory control, and supply chain optimization. This guide will explore the intricacies of Code 128 barcodes, delve into the features of popular barcode generator tools, and provide practical insights on how to effectively generate, integrate, and use these versatile barcodes.

Table of Contents

Code 128, a highly adaptable barcode symbology, stands out for its ability to encode a wide range of data, including numbers, letters, and special characters. Its robust structure and flexibility make it a popular choice across various industries, from manufacturing and logistics to healthcare and retail.

Introduction to Barcode Generator 128

Barcode Generator 128 is a versatile tool used to create barcodes that encode data in a structured format. This type of barcode can store a variety of information, such as product identifiers, serial numbers, and batch codes, enabling efficient data capture and processing.

Barcode Generator 128 is an essential tool for businesses and organizations looking to streamline their operations and improve efficiency. It offers several benefits, including:

Benefits of Using Barcode Generator 128

- Increased Efficiency: Barcode Generator 128 allows for quick and accurate data input, reducing manual errors and speeding up processes.

- Improved Accuracy: The use of barcodes eliminates the need for manual data entry, minimizing the risk of human errors.

- Enhanced Inventory Management: Barcodes provide real-time tracking of inventory levels, allowing for better stock control and reduced waste.

- Streamlined Supply Chain: Barcode Generator 128 enables efficient tracking of goods throughout the supply chain, improving visibility and reducing delays.

- Cost Savings: By automating data capture and processing, Barcode Generator 128 can significantly reduce labor costs and improve overall efficiency.

Industries and Applications of Barcode Generator 128

Barcode Generator 128 is widely used in various industries, including:

- Retail: Point-of-sale (POS) systems use barcodes for product identification, pricing, and inventory management.

- Manufacturing: Barcode Generator 128 is used for tracking production parts, managing inventory, and controlling quality.

- Healthcare: Barcodes are used for patient identification, medication tracking, and blood sample management.

- Logistics and Shipping: Barcode Generator 128 is crucial for tracking shipments, managing deliveries, and ensuring accurate package identification.

- Libraries: Barcodes are used for book identification, checkout, and inventory management.

Generating Barcodes with Barcode Generator 128

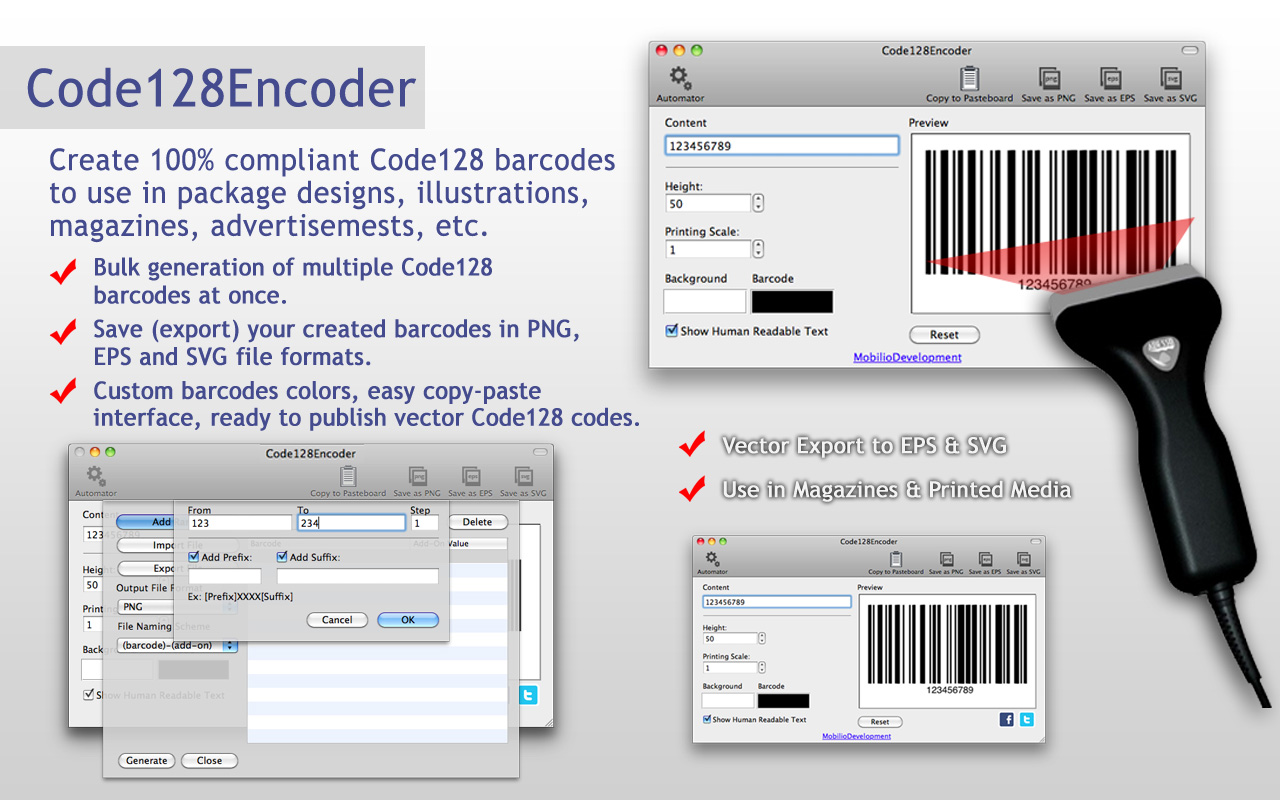

This section will guide you through the process of generating Code 128 barcodes using a barcode generator tool. We will explore how to input data, select the appropriate symbology, and customize the appearance of your barcodes. We will also showcase examples of generated barcodes with different data formats and encoding methods.

Understanding the Process of Generating Code 128 Barcodes

Generating Code 128 barcodes involves a few key steps:

- Data Input: Begin by entering the data you want to encode into the barcode. This data can include numbers, letters, and special characters.

- Symbology Selection: Choose Code 128 as the barcode symbology. This ensures the correct encoding and format for your barcode.

- Customization Options: You can customize the barcode’s appearance, such as its height, width, and color.

- Barcode Generation: Once you have entered the data, selected the symbology, and made any necessary customizations, click the “Generate” button to create your barcode.

Data Input and Encoding

Data input is the first step in creating a Code 128 barcode. Code 128 supports a wide range of characters, including numbers, letters, and special characters. The data you enter will be encoded according to the selected Code 128 variant.

- Code 128A: Encodes uppercase letters, numbers, and control characters.

- Code 128B: Encodes uppercase letters, numbers, and special characters, including punctuation marks.

- Code 128C: Encodes only numbers, typically used for serial numbers and product identification.

Selecting the Right Symbology

Selecting the correct symbology is crucial for ensuring your barcode is properly read by scanners. Code 128 is a high-density barcode symbology, meaning it can store a significant amount of data in a relatively small space.

“Code 128 is a versatile barcode symbology suitable for a wide range of applications.”

Customization Options

Barcode generators typically offer a range of customization options to tailor the appearance of your barcodes.

- Barcode Height: Adjust the height of the barcode to suit your needs.

- Barcode Width: Adjust the width of the barcode to control the size of the barcode.

- Barcode Color: Choose the color of the barcode lines and the background color.

- Text Display: Add text to the barcode, such as the encoded data or a label.

Examples of Generated Barcodes

Here are some examples of Code 128 barcodes generated with different data formats and encoding methods:

- Example 1: A Code 128A barcode encoding the text “ABC123”.

- Example 2: A Code 128B barcode encoding the text “Product ID: 1234567890”.

- Example 3: A Code 128C barcode encoding the number “1234567890”.

Barcode Generator 128 and Data Management

Barcode Generator 128 plays a crucial role in data management and tracking by enabling efficient and accurate identification and organization of information. This technology streamlines processes, improves accuracy, and provides valuable insights for informed decision-making.

Inventory Control

Barcode Generator 128 revolutionizes inventory management by providing a reliable system for tracking and monitoring stock levels.

- Real-time Inventory Tracking: Barcodes allow for instant identification and updating of inventory levels, eliminating manual counting and reducing errors. This real-time data provides accurate information on stock availability, enabling efficient replenishment and preventing stockouts.

- Automated Inventory Management: Barcode scanning integrates seamlessly with inventory management software, automating processes like receiving, storing, and shipping. This automation reduces manual labor, minimizes human error, and streamlines operations.

- Improved Inventory Accuracy: Barcodes eliminate the potential for manual errors associated with data entry, ensuring accurate inventory records. This accuracy leads to better stock control, reduced waste, and optimized resource allocation.

Asset Management

Barcode Generator 128 simplifies asset management by providing a robust system for tracking and monitoring valuable assets.

- Asset Tracking and Location: Barcodes enable real-time tracking of assets, providing information on their location, condition, and usage. This information facilitates efficient asset allocation, maintenance scheduling, and security measures.

- Asset Lifecycle Management: Barcodes track the entire lifecycle of an asset, from acquisition to disposal. This comprehensive tracking provides valuable insights into asset utilization, depreciation, and potential replacement needs.

- Improved Asset Security: Barcodes can be used for access control and security measures, restricting unauthorized access to sensitive assets. This enhanced security protects valuable equipment and reduces the risk of theft or damage.

Supply Chain Optimization

Barcode Generator 128 enhances supply chain efficiency by providing real-time visibility and control over the movement of goods.

- Real-time Tracking of Goods: Barcodes enable real-time tracking of goods throughout the supply chain, providing visibility into their location, status, and movement. This information facilitates efficient logistics planning, timely delivery, and improved customer satisfaction.

- Enhanced Supply Chain Transparency: Barcodes create transparency throughout the supply chain, enabling stakeholders to track the origin, handling, and delivery of goods. This transparency builds trust, improves accountability, and fosters collaboration among supply chain partners.

- Reduced Inventory Costs: By optimizing inventory management and logistics, Barcode Generator 128 contributes to reduced inventory holding costs, transportation expenses, and overall supply chain costs.

Barcode Generator 128 and Integration

Barcode Generator 128 tools offer robust integration capabilities, allowing them to seamlessly interact with various software systems and enhance data flow within organizations. These tools facilitate the incorporation of barcodes into databases, spreadsheets, and other applications, streamlining workflows and improving data accuracy.

Integrating Barcodes into Databases

Barcode Generator 128 tools can directly integrate with database management systems, enabling the creation and management of barcode data within a centralized database. This integration simplifies data entry and retrieval, as barcodes can be scanned and their associated data automatically populated into the database.

For example, a retail store can integrate its barcode generator with a database to manage inventory. When a product is received, its barcode can be scanned, and the database will automatically update the inventory count. Similarly, when a product is sold, the barcode can be scanned, and the database will update the inventory count and sales data.

Integrating Barcodes into Spreadsheets

These tools can be integrated with spreadsheet software, allowing users to generate barcodes directly within spreadsheets. This integration simplifies the process of creating and managing barcodes within a spreadsheet environment.

For instance, a company can use a barcode generator to create barcodes for its products and then integrate these barcodes into a spreadsheet that tracks inventory levels. This allows the company to easily manage its inventory by scanning barcodes and updating the spreadsheet.

Integrating Barcodes into Other Applications

Barcode Generator 128 tools can integrate with various other applications, such as point-of-sale (POS) systems, warehouse management systems (WMS), and customer relationship management (CRM) systems. This integration enhances data flow and automates processes across different systems.

For example, a logistics company can integrate its barcode generator with its WMS to track shipments. When a shipment is received, its barcode can be scanned, and the WMS will automatically update the shipment status. This information can then be shared with other systems, such as the CRM system, to keep customers informed about their orders.

Printing and Using Code 128 Barcodes

Once you’ve generated your Code 128 barcodes, the next step is to print them and integrate them into your systems. Printing Code 128 barcodes involves considerations like printer type, resolution, print quality, and placement. This section will provide guidance on printing Code 128 barcodes effectively, ensuring they are readable and reliable.

Printer Types and Printing Methods

Code 128 barcodes can be printed using various printer types and methods, each with its own advantages and limitations. Here’s a breakdown of common options:

- Thermal Printers: These printers use heat to transfer ink onto special thermal paper. They are commonly used for labels, receipts, and other applications where high print volume is required. Thermal printers are relatively inexpensive and offer good print quality for Code 128 barcodes.

- Laser Printers: Laser printers use a toner-based printing process, offering high-quality prints on various paper types. They are suitable for printing barcodes on documents, labels, and packaging materials. Laser printers are generally more expensive than thermal printers but offer better print quality and durability.

- Inkjet Printers: Inkjet printers use ink cartridges to print images and text. They are a versatile option for printing barcodes on various surfaces, including paper, cardstock, and envelopes. Inkjet printers offer lower print volume and may not be as durable as thermal or laser printers, but they are widely available and affordable.

Barcode Resolution and Print Quality

The resolution and print quality of your barcodes are crucial for accurate scanning. Here’s what to keep in mind:

- Resolution: Aim for a minimum resolution of 300 DPI (dots per inch) for Code 128 barcodes. Higher resolutions, like 600 DPI or even 1200 DPI, can provide even better readability, especially for smaller barcodes or those printed on textured surfaces.

- Print Quality: Ensure that the barcode is printed clearly and without any smudging, fading, or distortion. Avoid using low-quality ink or paper, as this can affect barcode readability.

Barcode Placement and Best Practices

Proper placement of your Code 128 barcodes is essential for efficient scanning. Here are some best practices to follow:

- Clear Background: Ensure the barcode is printed on a plain background without any distracting patterns or images. A solid white or light-colored background is ideal.

- Adequate Space: Leave sufficient space around the barcode to avoid interference from other elements on the printed material.

- Barcode Orientation: Ensure the barcode is printed in the correct orientation. Code 128 barcodes are typically read from left to right.

- Contrast: The barcode should have sufficient contrast between the bars and spaces. This means the bars should be dark enough and the spaces light enough for the scanner to differentiate them.

Security Considerations for Code 128 Barcodes

While Code 128 barcodes offer efficiency and convenience, security remains a crucial aspect. Understanding potential vulnerabilities and implementing preventative measures is essential for maintaining data integrity and preventing fraudulent activities.

Preventing Barcode Counterfeiting, Barcode generator 128

Counterfeiting is a serious concern for businesses relying on Code 128 barcodes for product identification and inventory management. Implementing robust security measures can significantly reduce the risk of counterfeiting.

- Using Encrypted Data: Encrypting the data encoded within the barcode makes it difficult for counterfeiters to decipher and replicate the information. This can be achieved using various encryption algorithms and keys.

- Implementing Checksum Verification: Adding a checksum digit to the barcode data provides an extra layer of security. This digit is calculated based on the encoded data and can be used to validate the barcode’s authenticity.

- Employing Unique Identifiers: Assigning unique identifiers to each barcode, such as serial numbers or product-specific codes, can make it challenging for counterfeiters to create identical barcodes.

- Utilizing Secure Printing Techniques: Employing printing methods that are difficult to replicate, such as microprinting, holographic features, or special inks, can deter counterfeiters.

Data Manipulation Prevention

Preventing data manipulation within Code 128 barcodes is critical for maintaining accurate records and preventing fraudulent activities.

- Data Integrity Verification: Implementing mechanisms to verify the integrity of the data encoded within the barcode is essential. This can involve checksum verification, error detection codes, or other data validation techniques.

- Barcode Authentication: Utilizing barcode authentication systems that verify the authenticity of the barcode and the data it represents can significantly reduce the risk of manipulation.

- Secure Barcode Generation: Implementing secure barcode generation processes, such as using certified software or hardware, can help ensure that the barcodes are created with integrity and cannot be easily manipulated.

- Access Control: Limiting access to barcode generation and data management systems can help prevent unauthorized manipulation of barcode data.

Enhancing Barcode Integrity

Integrating security features into Code 128 barcodes can enhance their integrity and deter fraudulent activities.

- Digital Signatures: Implementing digital signatures on barcode data provides a verifiable proof of origin and authenticity. This involves using cryptographic techniques to sign the data, ensuring its integrity and preventing unauthorized modifications.

- Time-Stamping: Adding a timestamp to the barcode data can help track the barcode’s creation date and time, providing evidence of its legitimacy and preventing manipulation of the creation date.

- Watermarking: Embedding watermarks within the barcode image can serve as a hidden identifier, making it difficult to counterfeit the barcode without revealing the watermark.

Best Practices for Using Barcode Generator 128

Optimizing your use of Barcode Generator 128 tools is crucial for efficient data management, accurate inventory tracking, and seamless integration into your processes. By following these best practices, you can ensure the integrity and effectiveness of your barcodes, leading to smoother operations and improved overall efficiency.

Data Input

Accurate data input is the foundation of reliable barcode generation. Ensure data integrity and consistency for accurate barcode representation.

Barcode generator 128 is a versatile tool for creating barcodes that can encode a wide range of data, including alphanumeric characters and special symbols. This makes it ideal for various applications, especially in industries like automotive, where precise identification and traceability are crucial.

The AUTOSAR standard, which focuses on automotive software architecture, can benefit from barcode generator 128 by utilizing its capabilities for component identification and tracking throughout the manufacturing and lifecycle management processes.

- Use a Standardized Data Format: Implement a consistent data format for all entries, including consistent capitalization, punctuation, and special character usage. This ensures uniform barcode representation and eliminates potential errors caused by inconsistent input.

- Validate Data Before Generation: Employ data validation checks to identify and rectify potential errors before generating barcodes. This step helps prevent the creation of invalid or inaccurate barcodes.

- Use Check Digits: Integrate check digits into your data structure. These digits act as error detection mechanisms, verifying the accuracy of data during barcode scanning. This enhances data integrity and helps identify potential errors during the scanning process.

Barcode Design

Designing barcodes that are easily readable and suitable for your application is crucial for efficient scanning and data capture.

- Choose the Right Barcode Symbology: Select the appropriate barcode symbology for your needs. Code 128 is versatile and suitable for various applications, but consider factors like data length, density, and specific requirements for your use case. For instance, if you need to encode a large amount of data, consider using a symbology that can accommodate long data strings.

- Optimize Barcode Size and Resolution: Determine the optimal barcode size and resolution for your printing method and scanning equipment. Smaller barcodes may be suitable for labels, while larger barcodes are better for larger surfaces. Ensure sufficient resolution for clear barcode representation and accurate scanning.

- Include Quiet Zones: Ensure adequate quiet zones (empty spaces) around the barcode. These zones prevent interference from adjacent markings and ensure accurate scanning. The size of the quiet zone is dependent on the barcode symbology and should be adhered to for optimal performance.

- Use High-Contrast Colors: Select contrasting colors for the barcode and background. Dark bar elements on a light background or vice versa provide optimal visibility and facilitate accurate scanning. Consider the environment where the barcodes will be used and choose colors that provide good contrast in that setting.

Printing

Printing barcodes correctly ensures their readability and accuracy during scanning.

- Use High-Quality Printers: Employ high-quality printers that can produce clear and precise barcodes. This minimizes distortion and ensures accurate scanning. Consider printers specifically designed for barcode printing for optimal results.

- Calibrate Printers Regularly: Calibrate your printers regularly to maintain consistent print quality. This ensures that barcodes are printed to the correct size and resolution, minimizing scanning errors. Regular calibration ensures that the printer produces consistent and accurate barcodes, preventing issues related to distortion or misalignment.

- Use Durable Materials: Select durable materials for printing labels or tags. This ensures that barcodes remain legible and scannable even under harsh conditions. Consider the environment where the barcodes will be used and choose materials that can withstand wear and tear.

- Avoid Overlapping or Distorted Barcodes: Ensure that barcodes are printed without overlapping or distortion. Overlapping elements can interfere with scanning, while distortion can make the barcode unreadable.

Security

Security considerations are crucial for protecting data integrity and preventing unauthorized access or manipulation.

- Use Encryption: Implement encryption techniques to protect sensitive data encoded within barcodes. Encryption safeguards data from unauthorized access, ensuring the integrity of information.

- Implement Access Control: Establish access control mechanisms to restrict unauthorized access to barcode generation tools and data. This helps prevent the creation of fraudulent or unauthorized barcodes.

- Use Digital Signatures: Integrate digital signatures to authenticate barcodes and ensure data integrity. Digital signatures provide a tamper-evident mechanism, verifying the authenticity and integrity of the barcode.

Future Trends in Barcode Generator 128

The world of barcode technology is constantly evolving, with new advancements and trends emerging regularly. Barcode Generator 128 tools are expected to adapt and integrate these innovations, leading to more efficient, versatile, and secure barcode solutions. This section explores some of the key future trends that will shape the landscape of barcode generation and utilization.

Emerging Barcode Technologies

The advancement of barcode technology is driven by several key factors, including the need for enhanced data storage, increased security, and improved efficiency. These factors are fueling the development of new barcode standards and applications.

- High-Density Barcodes: Traditional barcodes have limitations in the amount of data they can encode. High-density barcodes, such as Data Matrix and QR codes, can store significantly more information within a smaller area, enabling more complex data to be encoded. This is particularly useful for applications like product tracking, inventory management, and secure authentication.

- 2D Barcodes: 2D barcodes, like QR codes, have become increasingly popular due to their ability to store large amounts of data and provide access to online content. These codes can be easily scanned using smartphones, making them ideal for marketing campaigns, product information, and interactive experiences.

- Biometric Barcodes: Biometric barcodes leverage unique biological characteristics, such as fingerprints or iris scans, for identification and authentication. This technology offers enhanced security and can be used in various applications, including access control, identity verification, and healthcare.

- Near Field Communication (NFC) Barcodes: NFC technology enables contactless communication between devices. NFC barcodes can be integrated into physical objects, allowing for seamless data exchange and interaction. This technology has potential applications in mobile payments, product authentication, and supply chain management.

Resources and Further Learning

This section will provide a list of reputable resources for learning more about Code 128 barcodes and barcode generators. We’ll share links to relevant websites, articles, and documentation to help you further your understanding of this technology.

Online Resources

The internet is a vast resource for learning about Code 128 barcodes. Here are some websites that can help you expand your knowledge:

- GS1: GS1 is a global organization that develops and maintains standards for barcodes, including Code 128. Their website offers a wealth of information about the standard, including technical specifications, implementation guidelines, and best practices. https://www.gs1.org/

- Wikipedia: Wikipedia is a great starting point for learning about Code 128 barcodes. The entry provides a concise overview of the standard, its history, and its applications. https://en.wikipedia.org/wiki/Code_128

- Barcode Technology: Barcode Technology is a website dedicated to providing information about barcode technology. They offer articles, tutorials, and resources on various barcode standards, including Code 128. https://www.barcode-technology.com/

Documentation and Articles

There are many resources available that provide detailed documentation and articles on Code 128 barcodes:

- Code 128 Specifications: This document Artikels the technical specifications for Code 128 barcodes, including character sets, encoding rules, and checksum calculations. You can find this document on the GS1 website or other barcode technology websites.

- Barcode Generator 128 User Manuals: Most barcode generator software comes with comprehensive user manuals that provide step-by-step instructions on how to create and use Code 128 barcodes.

- Articles on Barcode Technology: Many articles are available online and in print that delve deeper into the technical aspects of Code 128 barcodes, their applications, and their advantages and disadvantages.

Further Exploration

To delve deeper into Code 128 barcodes, you can explore the following areas:

- Barcode Symbology: Explore other barcode symbologies besides Code 128, such as Code 39, UPC, EAN, and QR codes. Compare and contrast their features, advantages, and disadvantages.

- Barcode Scanning and Reading: Learn about the technology behind barcode scanners and how they read and decode barcodes. Investigate different types of scanners, their capabilities, and their limitations.

- Barcode Integration: Explore how barcodes are integrated into various systems and applications, such as inventory management, point-of-sale systems, and supply chain logistics.

Summary

Mastering the art of generating and utilizing Code 128 barcodes can significantly enhance efficiency, accuracy, and security within your operations. By understanding the nuances of Code 128, exploring the capabilities of barcode generator tools, and following best practices, you can leverage the power of these versatile barcodes to streamline processes and unlock new levels of productivity.