Remote monitoring and control systems have revolutionized the way we manage and interact with various systems, from industrial processes to personal devices. These systems enable real-time monitoring and control of equipment and processes from remote locations, enhancing efficiency, safety, and productivity.

Table of Contents

The concept of remote monitoring and control has evolved significantly over time, driven by advancements in communication technologies, sensor technology, and computing power. Early systems relied on wired connections and limited functionalities, while modern systems leverage wireless networks, cloud computing, and artificial intelligence to offer sophisticated capabilities.

Components of a Remote Monitoring and Control System

Remote monitoring and control systems (RMCS) are essential for optimizing operations, ensuring safety, and improving efficiency in various industries. These systems enable real-time monitoring of critical parameters and remote control of equipment, regardless of physical location.

Components of a Remote Monitoring and Control System

A typical RMCS consists of several interconnected components, each playing a crucial role in its functionality. The following table Artikels the key components and their respective roles:

| Component | Role and Function |

|---|---|

| Sensors | Sensors are responsible for collecting data from the physical environment. They convert physical parameters, such as temperature, pressure, flow rate, or vibration, into electrical signals that can be transmitted to the control unit. |

| Actuators | Actuators receive signals from the control unit and translate them into physical actions. They are responsible for controlling equipment, such as valves, motors, pumps, or heating elements. |

| Communication Networks | Communication networks facilitate the transmission of data between sensors, actuators, and the control unit. They provide a reliable and secure channel for data exchange, enabling real-time monitoring and control. |

| Control Unit | The control unit is the central processing unit of the RMCS. It receives data from sensors, processes it, and sends control signals to actuators. It also provides user interfaces for monitoring and control. |

| User Interfaces | User interfaces allow operators to interact with the RMCS. They provide a visual representation of system data, enable configuration settings, and allow for manual control. |

Types of Sensors and Actuators

Sensors and actuators are crucial components of RMCS, and their selection depends on the specific application and requirements.

Types of Sensors

Sensors can be categorized based on the physical parameter they measure. Some common types include:

- Temperature Sensors: Thermocouples, Resistance Temperature Detectors (RTDs), and Thermistors are commonly used to measure temperature. Each type has different advantages and disadvantages in terms of accuracy, range, and cost.

- Pressure Sensors: Strain gauge pressure sensors, piezoelectric sensors, and capacitive sensors are used to measure pressure. The choice depends on factors like pressure range, accuracy, and environmental conditions.

- Flow Sensors: Flow sensors, such as Coriolis mass flow meters, ultrasonic flow meters, and turbine flow meters, are used to measure the rate of fluid flow.

- Level Sensors: Level sensors, such as ultrasonic sensors, radar sensors, and float switches, are used to measure the level of liquids or solids in tanks or containers.

- Vibration Sensors: Accelerometers, velocity sensors, and displacement sensors are used to measure vibrations in machines or structures.

Advantages and Disadvantages of Sensors

The choice of sensor depends on the specific application and requirements. Each type has its own advantages and disadvantages:

- Thermocouples: Thermocouples are relatively inexpensive and can withstand high temperatures. However, they have lower accuracy than other types of temperature sensors.

- RTDs: RTDs offer high accuracy and stability but are more expensive than thermocouples.

- Thermistors: Thermistors are highly sensitive to temperature changes but have a limited temperature range.

- Strain Gauge Pressure Sensors: Strain gauge pressure sensors are accurate and reliable but can be susceptible to temperature variations.

- Piezoelectric Sensors: Piezoelectric sensors are sensitive to high-frequency vibrations but have a limited pressure range.

- Capacitive Sensors: Capacitive sensors are non-contacting and can measure level or proximity but are susceptible to environmental factors like dust or moisture.

Types of Actuators

Actuators are responsible for converting electrical signals into physical actions. Some common types include:

- Solenoid Valves: Solenoid valves are used to control the flow of fluids by opening or closing a valve using an electromagnetic coil.

- Electric Motors: Electric motors are used to rotate shafts and power various equipment, such as pumps, fans, and conveyors.

- Pneumatic Actuators: Pneumatic actuators use compressed air to provide linear or rotary motion. They are often used in applications where high force or torque is required.

- Hydraulic Actuators: Hydraulic actuators use hydraulic fluid to generate force and motion. They are commonly used in heavy-duty applications, such as construction equipment.

Advantages and Disadvantages of Actuators

The choice of actuator depends on the specific application and requirements. Each type has its own advantages and disadvantages:

- Solenoid Valves: Solenoid valves are relatively inexpensive and easy to control. However, they have limited force and speed capabilities.

- Electric Motors: Electric motors offer high efficiency and precise control. However, they can be more expensive than other types of actuators.

- Pneumatic Actuators: Pneumatic actuators are reliable and provide high force output. However, they require compressed air and can be noisy.

- Hydraulic Actuators: Hydraulic actuators provide high force and torque but are complex and require maintenance.

Control Strategies and Algorithms: Remote Monitoring And Control System

Remote monitoring and control systems rely on various control strategies and algorithms to ensure efficient and reliable operation. These strategies dictate how the system responds to changes in the monitored environment and adjusts the controlled parameters accordingly.

Feedback Control

Feedback control is a fundamental control strategy where the system uses the measured output to adjust the input, creating a closed-loop system. This continuous feedback loop allows the system to maintain the desired output value, even in the presence of disturbances.

- Proportional-Integral-Derivative (PID) Controller: PID controllers are widely used in feedback control systems due to their simplicity and effectiveness. They combine three control actions: proportional (P), integral (I), and derivative (D) to adjust the input based on the error between the desired and actual output. The proportional term provides immediate response to the error, the integral term eliminates steady-state errors, and the derivative term anticipates future errors.

- Fuzzy Logic Controller: Fuzzy logic controllers are based on fuzzy set theory, allowing them to handle complex, nonlinear systems. They use linguistic rules and fuzzy membership functions to map input variables to output values. Fuzzy logic controllers excel in situations where precise mathematical models are unavailable or difficult to obtain.

Feedforward Control

Feedforward control uses knowledge of disturbances and system dynamics to anticipate and compensate for potential changes in the output. Unlike feedback control, it does not rely on measuring the actual output.

- Predictive Control: Predictive control algorithms use models of the system and its environment to predict future outputs and adjust the input accordingly. They are often used in systems with significant time delays or complex dynamics.

- Model Predictive Control (MPC): MPC is a type of predictive control that uses an optimization algorithm to determine the best control sequence over a prediction horizon. It is commonly employed in industrial processes with multiple inputs and outputs.

Adaptive Control

Adaptive control strategies adjust the control parameters based on changes in the system or environment. They continuously learn and adapt to variations, ensuring optimal performance over time.

- Self-Tuning Controllers: Self-tuning controllers automatically adjust their control parameters based on real-time system behavior. They use online identification techniques to estimate the system parameters and update the controller accordingly.

- Reinforcement Learning Controllers: Reinforcement learning controllers learn from their experiences, adjusting their control actions based on rewards or penalties received. They are particularly suitable for complex systems with unknown dynamics or uncertain environments.

Performance Comparison of Control Strategies and Algorithms

| Control Strategy/Algorithm | Accuracy | Responsiveness | Robustness |

|---|---|---|---|

| PID Controller | High | Moderate | Moderate |

| Fuzzy Logic Controller | Moderate | Moderate | High |

| Model Predictive Control | High | High | Moderate |

| Self-Tuning Controller | High | High | High |

| Reinforcement Learning Controller | Moderate | High | High |

Data Acquisition and Processing

The foundation of any effective remote monitoring and control system lies in its ability to gather and interpret data from the field. Data acquisition and processing are crucial steps that transform raw sensor readings and actuator commands into actionable insights.

Data Acquisition from Sensors and Actuators

Data acquisition in remote monitoring and control systems involves gathering information from sensors and actuators deployed in the field. Sensors are devices that measure physical parameters such as temperature, pressure, flow, and level, while actuators are devices that control physical processes by manipulating variables like valves, motors, and pumps.

- Sensor Data: Sensors convert physical quantities into electrical signals that are then transmitted to the monitoring and control system. These signals can be analog or digital, depending on the type of sensor.

- Actuator Data: Actuator data involves monitoring the status and performance of actuators. This data can include position, speed, and current consumption, providing valuable insights into the effectiveness of control actions.

Data Processing Techniques

Once data is acquired, it needs to be processed to extract meaningful insights and facilitate decision-making. Several data processing techniques are employed in remote monitoring and control systems, including:

- Data Filtering: Data filtering is used to remove noise and unwanted disturbances from raw sensor readings. This process ensures that the data used for analysis and control is accurate and reliable. Various filtering techniques exist, such as moving average filters, Kalman filters, and wavelet filters.

- Data Aggregation: Data aggregation involves combining multiple data points into a single representative value. This technique is useful for reducing data volume, simplifying analysis, and identifying trends. For example, averaging hourly temperature readings over a day to obtain a daily average temperature.

- Data Visualization: Data visualization is a powerful technique for presenting data in a clear and understandable manner. It enables operators to quickly identify patterns, anomalies, and trends in the data, facilitating timely decision-making. Various visualization tools and techniques are available, including graphs, charts, dashboards, and maps.

Data Acquisition, Processing, and Analysis Flowchart

The following flowchart illustrates the steps involved in data acquisition, processing, and analysis in a remote monitoring and control system:

[Flowchart illustration description]

The flowchart demonstrates the sequential process of data acquisition, filtering, aggregation, and visualization, ultimately leading to actionable insights for decision-making.

Remote monitoring and control systems are crucial for managing and optimizing various processes, especially in industrial settings. One such system, murj remote monitoring , offers a comprehensive platform for real-time data acquisition, analysis, and control, enabling users to remotely monitor and adjust critical parameters, enhancing efficiency and reducing downtime.

User Interface and Human-Machine Interaction

A user-friendly interface is crucial for remote monitoring and control systems. It ensures that operators can easily access and interpret data, make informed decisions, and efficiently control equipment from remote locations. A well-designed interface promotes user satisfaction, reduces errors, and improves overall system effectiveness.

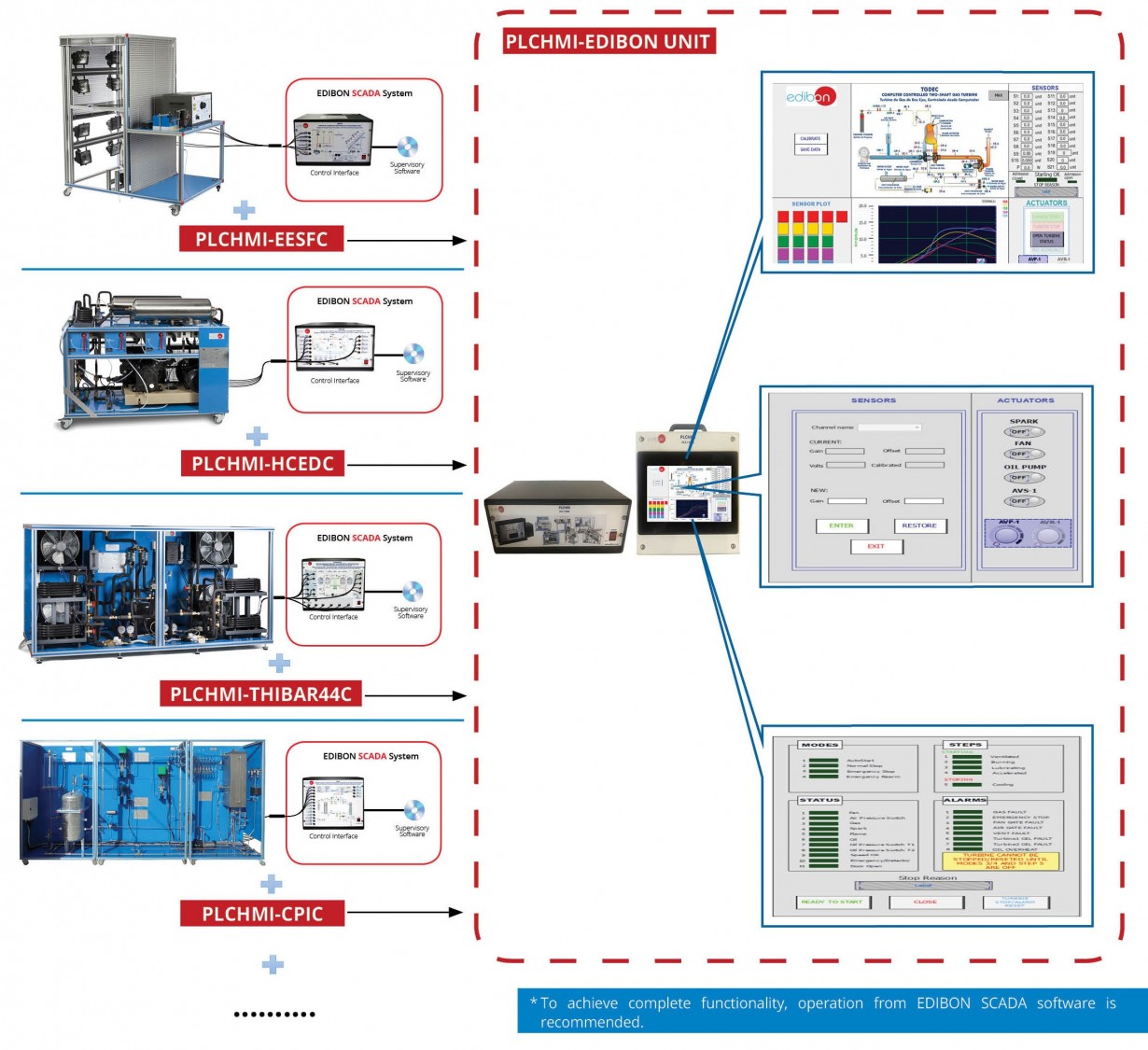

Types of User Interfaces

Different types of user interfaces cater to varying user needs and system complexities.

- Graphical User Interfaces (GUIs): GUIs offer a visually appealing and intuitive way to interact with systems. They use icons, menus, and graphical elements to represent data and control functions. GUIs are prevalent in modern systems, providing a user-friendly experience for both novice and experienced operators.

- Command-Line Interfaces (CLIs): CLIs rely on text-based commands for interacting with the system. They are typically used in scenarios requiring precise control or scripting, where speed and efficiency are prioritized. While less user-friendly than GUIs, CLIs offer a more direct and powerful way to manage complex systems.

- Mobile App Interfaces: Mobile app interfaces are designed for use on smartphones and tablets. They provide convenient access to remote monitoring and control functions from anywhere with an internet connection. Mobile app interfaces are often designed with simplified navigation and touch-optimized controls for ease of use.

Key Design Principles for User Interfaces

Effective human-machine interfaces are crucial for remote monitoring and control systems. The design should prioritize usability, clarity, and efficiency.

- Simplicity: The interface should be straightforward and easy to understand, avoiding unnecessary complexity.

- Consistency: Consistent layout, terminology, and interaction patterns throughout the interface promote user familiarity and reduce confusion.

- Clarity: Information should be presented clearly and concisely, using appropriate visuals and data representations.

- Feedback: The system should provide timely and informative feedback to users, confirming actions and indicating system status.

- Error Prevention: The interface should minimize the potential for user errors by providing clear guidance, validation checks, and appropriate warnings.

Applications of Remote Monitoring and Control Systems

Remote monitoring and control systems have revolutionized various industries, enabling greater efficiency, productivity, and safety. These systems provide real-time data and remote control capabilities, allowing for optimized operations and proactive decision-making.

Applications in Different Industries

Remote monitoring and control systems are widely implemented across various industries, offering significant advantages in terms of efficiency, productivity, and safety. Here’s a table showcasing some prominent applications:

| Industry | Applications | Examples |

|---|---|---|

| Manufacturing |

|

|

| Energy |

|

|

| Healthcare |

|

|

| Agriculture |

|

|

| Transportation |

|

|

Future Applications in Emerging Technologies

Remote monitoring and control systems are poised to play a pivotal role in shaping the future of emerging technologies like Industry 4.0 and the Internet of Things (IoT).

Industry 4.0

Industry 4.0, also known as the fourth industrial revolution, emphasizes the integration of physical and digital systems in manufacturing. Remote monitoring and control systems are crucial for enabling the following:

- Smart factories: Real-time data from sensors and connected devices allows for continuous monitoring and optimization of manufacturing processes, leading to improved efficiency and productivity.

- Predictive maintenance: By analyzing data from sensors and equipment, remote monitoring systems can predict potential failures and schedule maintenance proactively, minimizing downtime and production losses.

- Automated production lines: Remote control capabilities enable the automation of production processes, leading to increased efficiency, reduced human error, and improved safety.

Internet of Things (IoT)

The Internet of Things (IoT) connects billions of devices and sensors, generating vast amounts of data. Remote monitoring and control systems are instrumental in leveraging this data for:

- Smart cities: Remotely monitoring and controlling traffic flow, energy consumption, and environmental conditions in urban areas, leading to improved efficiency, sustainability, and quality of life.

- Smart homes: Remotely managing appliances, lighting, and security systems in homes, enhancing convenience, energy efficiency, and safety.

- Connected healthcare: Remote patient monitoring, telemedicine, and wearable health devices allow for continuous health tracking and proactive interventions, improving patient outcomes and reducing healthcare costs.

Challenges and Future Directions

Remote monitoring and control systems offer significant advantages in various industries. However, their implementation and operation face several challenges, and ongoing technological advancements are shaping their future.

Security Challenges, Remote monitoring and control system

Security is a paramount concern in remote monitoring and control systems, as they often handle sensitive data and control critical infrastructure.

- Cyberattacks: Remote systems are vulnerable to cyberattacks, such as denial-of-service attacks, data breaches, and malware infections, which can disrupt operations, compromise data integrity, and cause financial losses.

- Unauthorized Access: Unsecured access points or weak authentication mechanisms can allow unauthorized individuals to gain control of the system, leading to data theft, system manipulation, and potential safety hazards.

- Data Privacy: Remote systems often collect and transmit sensitive data, raising concerns about data privacy and compliance with regulations such as the General Data Protection Regulation (GDPR).

Reliability Challenges

Reliability is crucial for remote monitoring and control systems, as they need to operate consistently and accurately, especially in critical applications.

- Network Connectivity: Intermittent or unreliable network connections can disrupt data transmission, leading to delays, inaccurate readings, and potential system malfunctions.

- Hardware and Software Failures: Hardware failures, software bugs, or outdated components can compromise system functionality, leading to downtime and operational disruptions.

- Environmental Factors: Extreme temperatures, humidity, or electromagnetic interference can affect the performance of sensors and other components, leading to inaccurate data and control issues.

Scalability Challenges

As the demand for remote monitoring and control systems grows, scalability becomes a crucial factor.

- System Capacity: Scaling up the system to accommodate increasing numbers of sensors, devices, and data streams can be challenging, requiring efficient resource allocation and robust infrastructure.

- Data Storage and Processing: The volume of data generated by remote systems can quickly overwhelm storage and processing capabilities, requiring efficient data management and analysis techniques.

- User Interface and Accessibility: Maintaining a user-friendly and accessible interface for a large number of users and diverse roles can be complex, requiring a well-designed and scalable architecture.

Cost Challenges

The implementation and maintenance of remote monitoring and control systems can involve significant costs.

- Hardware and Software: The initial investment in hardware, software, and network infrastructure can be substantial, especially for large-scale deployments.

- Installation and Configuration: Professional installation, configuration, and ongoing maintenance can add to the overall cost, requiring specialized expertise and resources.

- Security and Compliance: Implementing robust security measures, complying with regulations, and addressing potential cyber threats can require significant investments in technology, personnel, and training.

Emerging Trends and Technologies

Technological advancements are driving the evolution of remote monitoring and control systems, enabling greater efficiency, scalability, and intelligence.

- Cloud Computing: Cloud computing offers a scalable and cost-effective platform for hosting remote monitoring and control systems, providing on-demand access to computing resources and data storage.

- Edge Computing: Edge computing brings data processing and analysis closer to the source, reducing latency and enabling real-time decision-making in remote environments.

- Artificial Intelligence (AI): AI algorithms can be used to analyze data from remote systems, identify patterns, predict trends, and optimize control strategies, enhancing efficiency and decision-making.

- Machine Learning (ML): ML algorithms can learn from historical data and adapt to changing conditions, enabling self-optimization and predictive maintenance in remote systems.

- Internet of Things (IoT): The proliferation of IoT devices is creating a vast network of connected sensors and actuators, enabling more comprehensive and granular remote monitoring and control capabilities.

Future Vision

Remote monitoring and control systems are poised to play an increasingly critical role in various industries and aspects of society.

- Smart Cities: Remote monitoring and control systems will be integral to the development of smart cities, enabling efficient management of traffic, energy consumption, and public services.

- Industrial Automation: Remote systems will drive further automation in manufacturing, logistics, and other industries, improving efficiency, productivity, and safety.

- Precision Agriculture: Remote monitoring and control systems will enable farmers to optimize crop yields, manage resources effectively, and improve sustainability.

- Healthcare: Remote patient monitoring systems will enhance healthcare delivery, allowing for personalized care, early detection of health issues, and improved patient outcomes.

Epilogue

Remote monitoring and control systems have become an integral part of modern industries and daily life. Their ability to provide real-time data, automate processes, and enhance decision-making has made them indispensable tools for optimizing performance, reducing costs, and improving safety. As technology continues to advance, we can expect even more sophisticated and integrated remote monitoring and control systems that will further transform various sectors.